The primary function of a brush is to deliver or collect current from a rotating part of an electric machine. The brushes should maintain a close contact with rotating part, (i.e. commutator or slipring) in order to ensure sparkless operation without wearing itself quickly. Carbon is a material, which meets all these requirements and its combination with certain other ingredients fulfils the specific requirements of a special machine.

At Ace Carbon we understand that making a good brush requires more than adherence to the customer's specifications. Our brush manufacturing department has in-depth knowledge and control over the raw material to ensure the desired microstructure in the material.

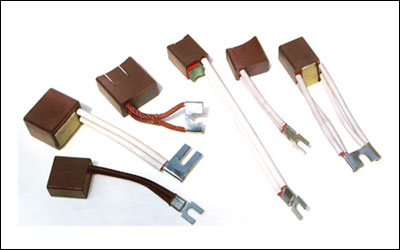

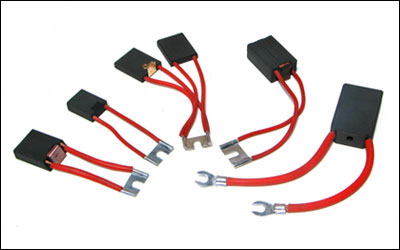

We have a wide range of design and sophisticated manufacturing capabilities to ensure an exact application. Carbon Brushes in different types of grades like (MG) Metal Graphite, (HC) Hard Carbon, (CG) Carbon Graphite, (SG) Silver Graphite, (EG) Electro graphitized, (RB) Resin Bonded, (NG) Natural Graphite find application in various types of electrical D.C. Motors, Slipring Motors, Variable Speed Motors, Traction Motors, Power Generator, Exciters, Welding Generators etc.

We have satisfied clients in diverse industries like Textile Mills, Paper Mills, Railways, Shipping, Steel Plants, Mines, Sugar Industries and Power Generators. We also fabricate carbon brushes for various power tools and home appliances for Black & Decker, Mico, Hitachi , Bosch, and Makita make.