Carbon gland rings are extensively used for restricting leakage from water and steam turbines.

For ease of fitting and replacement, the carbon rings are fabricated in segments. With the segments forming a complete ring encircled by a simple garter spring. Extremely fine tolerances are observed in the manufacture of these components to ensure their correct operation. A special feature of segments manufactured by us, is their complete interchangeability in rings of like design. In this particular application, sealing is affected by a small clearance between the bore of the rings and the tips of stubby fins on the shaft. Since rubbing contact between the fins and carbon rings, does not cause any damage, very small radial clearance can be used, resulting in a reduction in the leakage rate.

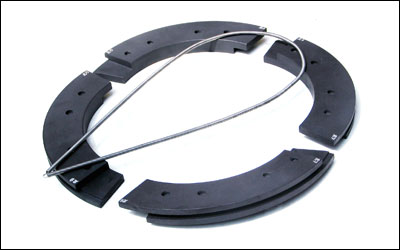

Specialized carbon turbine glands manufactured by us have also been supplied for water turbines in major hydroelectric installations. The wedge type rings shown in the illustration are typical of carbon gland ring arrangements installed at many hydroelectric power stations. Each ring is made up of segments. The ends of these segments are chamfered to present sliding surfaces to tapered wedge pieces, one of which is interposed between the ends of neighboring segments. A garter spring seated in a groove around the outside circumference of the ring holds the assembly of segments and wedges together. Wear on the carbon is taken up by the action of the spring and water pressure continually forcing the segments into contact with the shaft, while the wedges move out-wards. Thus a wear of the carbon segment takes place while they still maintain an effective seal.