The brush holder is not only of critical importance to the life and operating efficiency of the brush but in fact, to the life of the parent machine. The ability of the brush to perform is directly related to the design and quality of the brush holder which supports it against the commutator or slip ring.

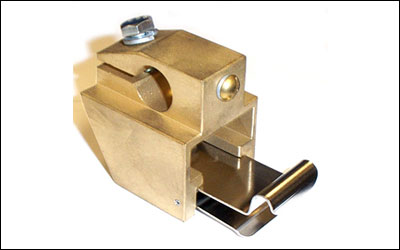

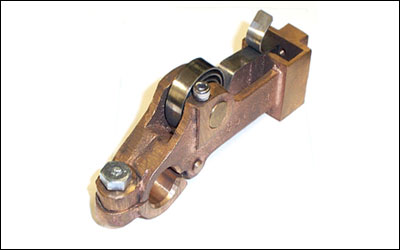

With an experience of over 40 years in this field our research department can boast of having developed the best possible materials for making the brush holders tailored to their specific applications. In the production of Brush holders we use only the highest grade of materials, such as brass sheet extrusions, Sand Castings, Brass Investment Castings etc. These materials are proven to show the best possible heat dissipation and highest resistance to mechanical strain.

To enhance the performance and life of brush holders, they can also be supplied with surface treatments against corrosion.

Our production range consists of Flange Brass holders, Clamps for brush holders, Double clamping brush holders, Leg brush holders, Tubular brush holders and brush holders for Traction Motors.